Let’s Build Smarter Conveyor Solutions Together

Whether you need a custom-built system or want to upgrade your existing setup, we're here to deliver precision, reliability, and performance.

A belt conveyor is a material handling system that consists of a continuous belt looped around two or more pulleys. It is used to transport goods, bulk materials, or products from one point to another efficiently. The belt is typically made of rubber, PVC, or other durable materials and moves over a series of rollers or a flat surface.

At Conveyor Tech Solutions, we provide high-performance belt conveyors designed for smooth, efficient, and cost-effective material transport. Built with durable materials and customizable options, our conveyors ensure seamless integration, minimal maintenance, and long-lasting reliability.

Ideal for industries like manufacturing, pharmaceuticals, food processing, and logistics, our solutions enhance productivity while reducing operational costs.

The Pharmaceutical Conveyor is built for precision, cleanliness, and compliance with industry regulations. Ideal for transporting vials, blister packs, capsules, syringes, and other sensitive products, it ensures reliable, contamination-free handling in pharmaceutical and cleanroom environments.

Depending on application needs, systems can be equipped with belt, modular, or flat-top chain designs, along with optional side guides, sensors, or integration with inspection and packaging lines.

Perfect for tablet production, filling lines, packaging zones, or lab automation, the Pharmaceutical Conveyor supports efficiency, accuracy, and compliance in every phase of the process.

A Belt Conveyor with Bag Sealing Machine is a compact, integrated solution designed for automated packaging lines. It combines continuous material transport with high-efficiency bag sealing, making it ideal for industries like food processing, agriculture, chemicals, and pharmaceuticals.

At Conveyor Tech Solutions, our Belt Conveyor with Bag Sealing Machine ensures smooth product flow from filling to final sealing. The conveyor moves filled bags directly to the sealing unit, where they are sealed using heat or impulse technology—depending on the material and application.

This setup significantly reduces manual handling, boosts packaging speed, and ensures consistent sealing quality perfect for products like grains, powders, snacks, seeds, chemicals, or hardware.

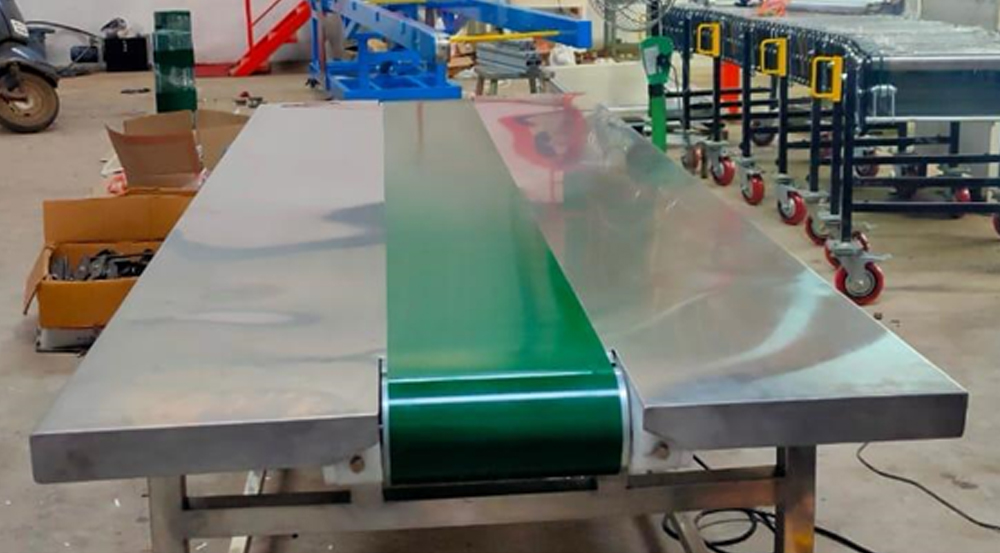

A Flat Belt Conveyor is one of the most commonly used conveyor systems for transporting products across short or long distances in a smooth, efficient manner. It features a continuous flat belt made of materials like PVC, PU, or rubber, which is driven by pulleys or rollers.

At Conveyor Tech Solutions, our Flat Belt Conveyors are designed for versatile, reliable, and low-maintenance operation in a wide range of industries, including manufacturing, packaging, food processing, pharmaceuticals, and logistics.

These conveyors are perfect for assembly lines, inspection systems, sorting stations, and more. Whether handling packed goods, raw materials, or loose items, our flat belt conveyors provide a cost-effective and dependable material handling solution.

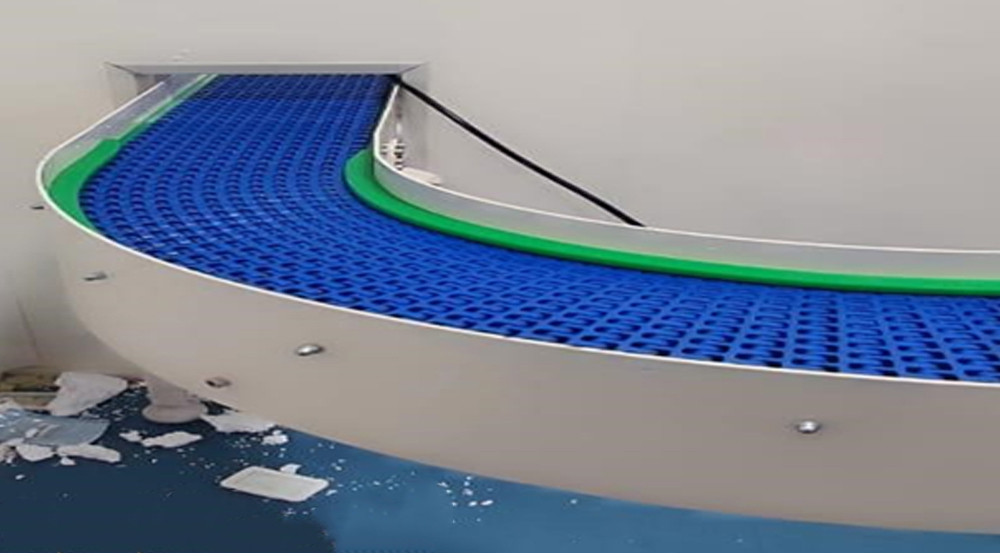

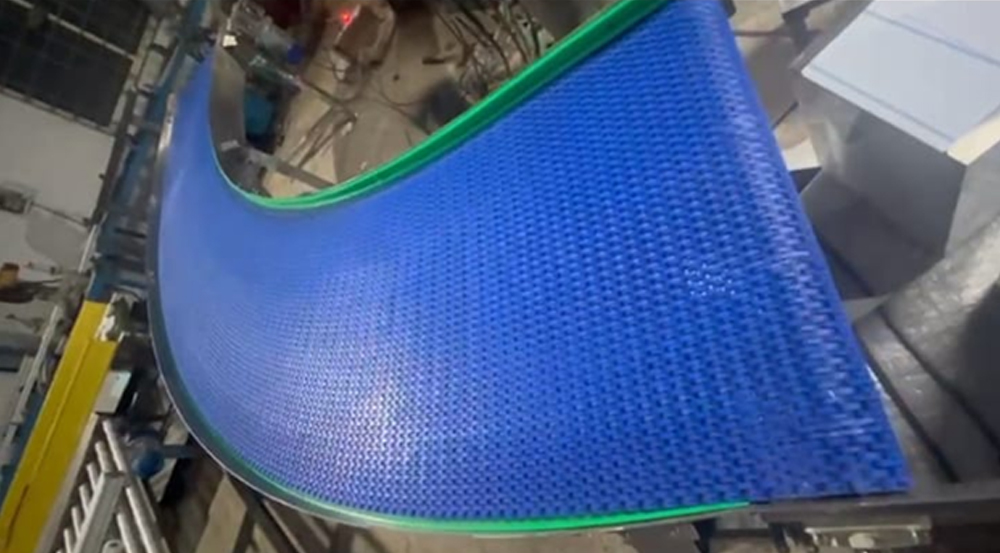

The Turning Modular Belt Conveyor is designed to smoothly transfer products around corners or curves without interrupting flow. Ideal for packaging lines, food processing, assembly systems, or distribution centers, this conveyor provides seamless directional changes while maintaining product stability and alignment.

Using interlocking modular plastic belt segments, it delivers excellent durability, quiet operation, and easy maintenance. The curved design can be customized to various turning angles typically 45°, 60°, 90°, or 180° to fit tight layouts or complex process paths. The modular surface allows airflow and drainage, making it suitable for both dry and washdown environments.

With strong support structure and low-friction operation, the Turning Modular Belt Conveyor is an ideal solution for space-efficient, continuous movement through turns, while minimizing wear and ensuring long service life.

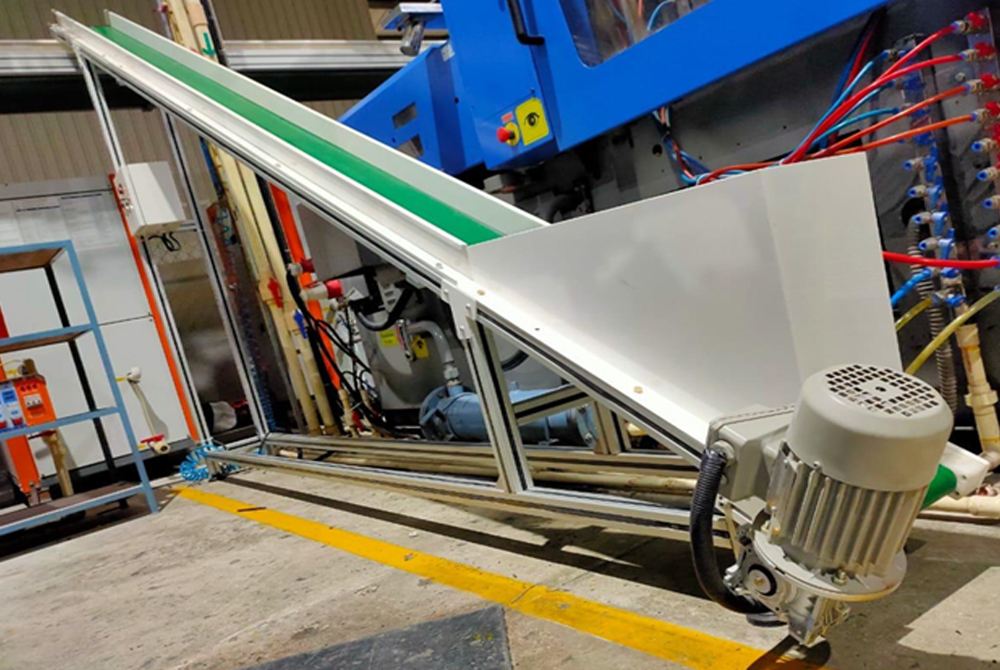

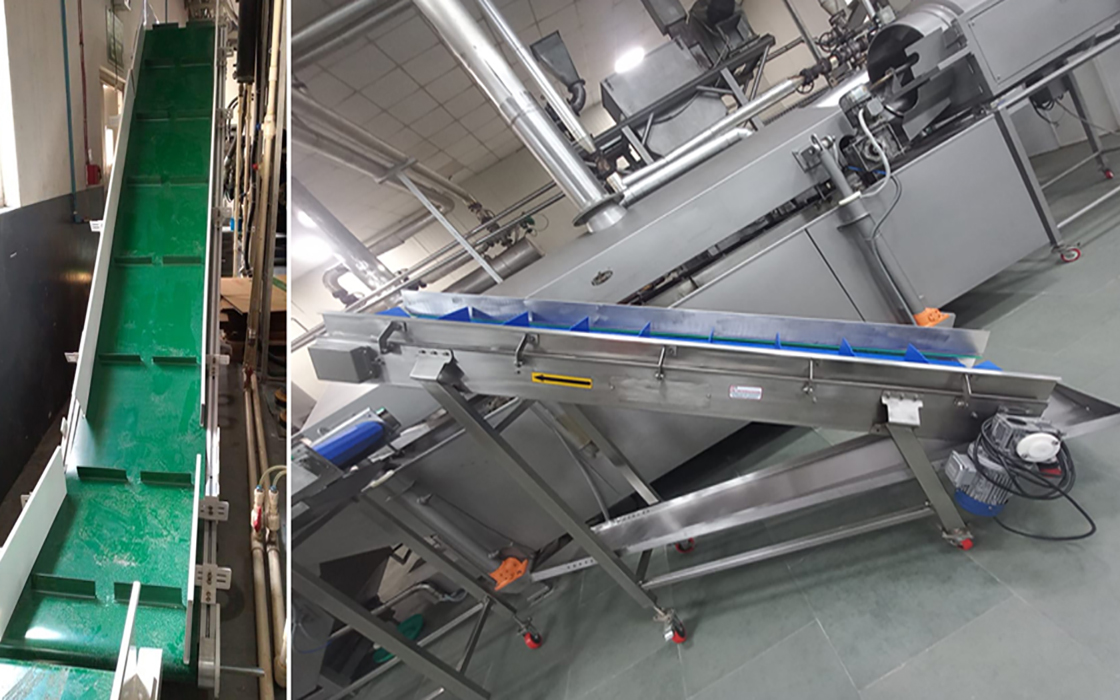

Conveyor Tech Solutions offers precision-engineered inclined belt conveyors designed to move materials safely and efficiently between different heights in your production line. Our conveyors are built to handle a wide range of materials from light packages to bulk products ensuring smooth transfer with minimal spillage.

Manufactured using high-quality materials and robust components, these conveyors are ideal for industries such as packaging, food processing, agriculture, logistics, and manufacturing. Available with custom belt types, side guards, and adjustable angles, our inclined belt conveyors provide flexibility to suit various applications and space constraints.

With a focus on performance and reliability, Conveyor Tech Solutions delivers complete conveyor solutions, including design, manufacturing, installation, and support.

The cleated white Belt Conveyor is designed to provide reliable elevation of products between different levels within your facility while maintaining a clean, streamlined appearance. Whether used in packaging, light assembly, inspection stations, or cleanroom environments, this conveyor offers a smooth and controlled way to move product upward or downward with precision and efficiency.

Equipped with a durable white belt made from PVC or polyurethane, this conveyor delivers excellent tracking, clean handling, and resistance to wear. The white color is ideal for applications that require better visibility for product inspection or a cleaner aesthetic, often used in industries like pharmaceuticals, cosmetics, electronics, and general light manufacturing.

The inclined frame is available in mild steel, aluminum, or stainless steel depending on your environment and sanitation needs. Optional cleats can be added to the belt to secure products on steeper inclines, and side rails can be configured to guide products and prevent spillage. Adjustable leg supports allow the incline angle and height to be fine-tuned to fit your process requirements.

An assembly line belt conveyor is a type of material handling system used in manufacturing environments to transport products or components from one workstation to another. It consists of a continuous belt loop powered by a motor, allowing for smooth and consistent movement of items along the production line. These conveyors are commonly used in industries such as automotive, electronics, packaging, and consumer goods, where repetitive and efficient transport is essential.

The belt can be made from materials like PVC, rubber, or modular plastic, depending on the product type and working conditions. Assembly line belt conveyors can be designed with adjustable speeds, integrated workstations, and custom dimensions to suit specific production requirements. By automating product flow, these conveyors help increase productivity, reduce manual handling, and streamline the overall assembly process.

In printing operations, precision and timing are everything. Conveyor Tech Solutions offers specialized printing belt conveyors designed to synchronize perfectly with your printing processes, ensuring smooth material flow, accurate positioning, and flawless print quality.

These systems integrate seamlessly with screen printers, inkjet printers, label applicators, and UV curing stations — making them ideal for industries such as packaging, labels, textiles, and commercial printing. Whether you need a straight run or customized with variable speed controls and sensors, each conveyor is tailored to your production flow.

At Conveyor Tech Solutions, we combine reliable design with expert engineering to create conveyor systems that keep your printing lines efficient, accurate, and hassle-free.

When your production line demands flexibility, durability, and easy maintenance, modular belt conveyors are the perfect solution. At Conveyor Tech Solutions, our modular belt conveyors are designed for flexibility, durability, and seamless product transfer. Unlike conventional belt systems, these conveyors use interlocking plastic segments, creating a robust and adaptable surface that resists wear, handles curves, and allows for easy repairs.

Perfect for industries like food processing, packaging, pharmaceuticals, and logistics, modular belt conveyors offer superior hygiene, easy cleaning, and the ability to transport products of all shapes and sizes without interruption. Whether you need straight-line conveying, elevation changes, or tight turns, our custom-built systems ensure optimal efficiency with minimal downtime.

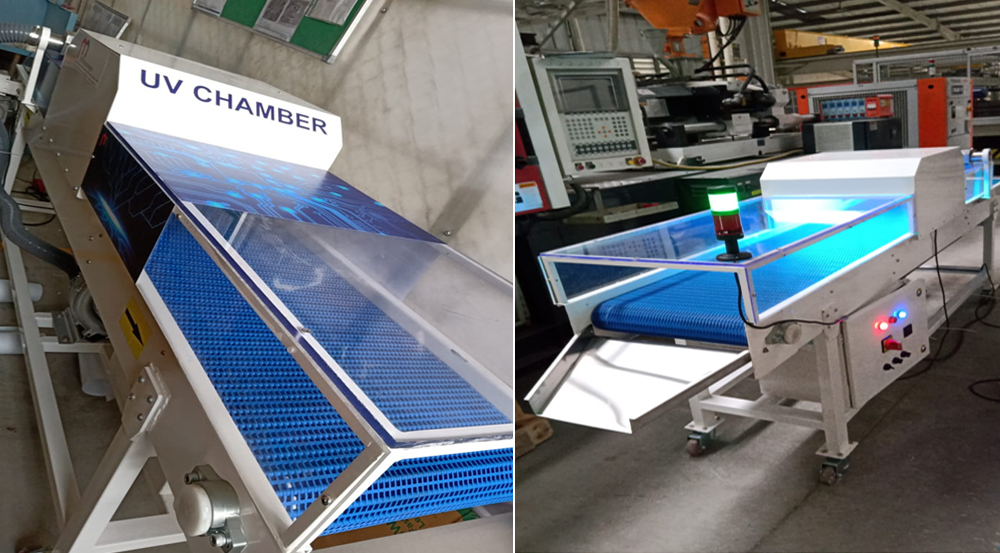

At Conveyor Tech Solutions, our UV chamber conveyors are designed to deliver precise and efficient ultraviolet treatment for a wide range of industrial applications. These conveyors integrate precision-controlled ultraviolet light chambers to ensure consistent exposure, whether for curing UV-sensitive coatings, adhesives, or for sterilizing surfaces and components.

Each system is designed for optimal safety and efficiency, featuring fully enclosed UV chambers to prevent light leakage and ensure operator protection. The conveyor speed can be adjusted to meet specific exposure requirements, while advanced cooling mechanisms maintain stable operating temperatures.

Built with UV-resistant materials and durable components, our conveyors are ideal for demanding environments such as pharmaceutical manufacturing, electronics assembly, printing, and medical device production.

A Z-shape belt conveyor is a versatile conveying solution designed to move materials vertically while conserving floor space. Its unique Z-configuration—horizontal-incline-horizontal—makes it ideal for lifting products from one level to another, such as from a hopper to a packaging machine or between floors in a production facility.

At Conveyor Tech Solutions, our Z-shape belt conveyors are custom-built for efficient product elevation, especially in environments where space is limited. These systems often feature cleated or modular belts to securely hold items in place as they move upward or downward. They're widely used in industries like food processing, pharmaceuticals, agriculture, and manufacturing.

We offer food-grade options, stainless steel frames for hygienic environments, and heavy-duty builds for industrial use. Each conveyor is engineered for reliable performance, easy cleaning, and smooth product flow.

A cleat belt conveyor is a type of belt conveyor system that features cleats—raised sections or barriers attached to the belt surface.The Inclined Cleat Belt Conveyor is designed for moving products between different elevations while preventing rollback or slippage. With cleats securely attached to the belt, it offers stable and efficient transport of bulk materials, parts, or packaged goods on an incline.

At Conveyor Tech Solutions, our cleat belt conveyors are engineered for handling bulk materials, packaged goods, or small parts that require elevation or controlled spacing during transport. These systems are commonly used in industries such as food processing, agriculture, pharmaceuticals, and manufacturing.

Our cleat belts are available in a range of materials (PVC, rubber, PU) and cleat designs (straight, angled, or custom-molded) to suit different product types and load requirements. Each conveyor is built to customer specifications, offering adjustable speed, durable construction, and compatibility with automated systems.

A food grade belt conveyor is a specialized conveyor system designed to safely handle food products while meeting hygiene and safety standards required in food processing environments.

These conveyors feature belts made of food-safe materials such as PU (polyurethane) or modular plastic, and are easy to clean, often with a wash-down-ready design.

Ideal for applications like baking, meat and poultry processing, dairy, fruits and vegetables, or packaged food products, these conveyors are tailored to maintain product integrity while streamlining production. Our systems can be configured for incline or horizontal transport, with options for cleats, side guides, and variable speeds to suit your specific needs.

The Chevron Belt Conveyor by Conveyor Tech Solutions is engineered for transporting bulk materials on steep inclines, where standard flat belts can’t maintain grip. Featuring a V-patterned cleated surface, the chevron belt provides excellent traction, minimizing material rollback and maximizing throughput on challenging gradients.

Ideal for handling loose or bulk materials such as grains, coal, sand, fertilizers, or packaged goods, this conveyor is widely used in agriculture, mining, recycling, and material processing industries. The chevron cleats guide materials securely along the belt, ensuring smooth and controlled movement even on steep inclines up to 30–40°, depending on the load.

Constructed with heavy-duty frames and high-tensile belts, the system is built for durability in demanding environments. Optional belt widths, cleat heights, and incline angles are available to match your specific application and material type.

The Belt Conveyor for Bag Printing from Conveyor Tech Solutions is designed to provide stable, accurate transport of bags for high-quality inline printing. Whether printing batch codes, expiry dates, barcodes, or logos, this conveyor ensures perfect print positioning at production speed.

Suitable for use with inkjet, thermal inkjet, or contact coders, it handles a wide variety of bag types plastic, paper, woven, or laminated. The smooth, low-vibration belt surface ensures clean, smudge-free printing, while adjustable speed and printer mounting options allow for easy integration into new or existing lines.

Ideal for food, fertilizer, chemical, and general packaging industries, this conveyor supports increased automation, reduced manual handling, and consistent marking results.

Whether you need a custom-built system or want to upgrade your existing setup, we're here to deliver precision, reliability, and performance.